Introduction

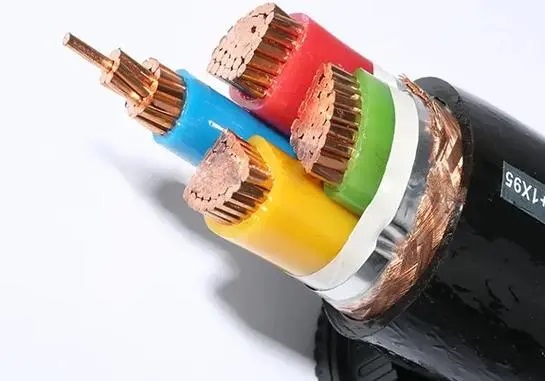

Photovoltaic (PV) systems have become a popular and effective way to harness solar energy for various applications, including residential, commercial, and industrial purposes. These systems consist of multiple components that work together to capture sunlight and convert it into usable electricity. One crucial component of a PV system is the cables that connect the solar panels to the inverter and other electrical equipment. These cables play a vital role in transferring the generated electricity efficiently and safely.

One of the challenges faced by PV cable systems is corrosion, which can significantly impact their performance and longevity. Corrosion can occur due to various factors such as exposure to environmental elements, moisture, temperature fluctuations, and chemical reactions. Therefore, it is essential to enhance the corrosion resistance of PV cables to ensure the reliability and durability of the overall system.

This article will explore the importance of corrosion resistance in PV cables, the factors contributing to corrosion, common types of corrosion, and strategies to improve corrosion resistance in PV cables. By understanding these key aspects, stakeholders in the solar industry can make informed decisions to enhance the performance and longevity of PV systems.

Importance of Corrosion Resistance in PV Cables

Corrosion resistance is a critical factor in the design and manufacturing of PV cables. PV systems are typically installed in outdoor environments where they are exposed to various weather conditions, including rain, snow, humidity, and temperature fluctuations. These environmental factors can accelerate the corrosion process, leading to degradation of the cables and potential safety hazards.

Corrosion in PV cables can result in several detrimental effects, including:

1. Electrical Resistance: Corrosion can increase the electrical resistance of the cables, leading to power losses and decreased energy efficiency of the system. Higher electrical resistance can also cause overheating of the cables, posing a fire risk.

2. Mechanical Strength: Corrosion can weaken the structural integrity of the cables, making them more susceptible to physical damage and failure. This can result in interruptions to the electricity supply and increased maintenance costs.

3. Safety Hazards: Corrosion in PV cables can compromise the safety of the system by increasing the risk of electrical faults, short circuits, and potential electrocution hazards to personnel working on the system.

Given these potential risks and challenges associated with corrosion in PV cables, it is imperative to prioritize corrosion resistance in the design, selection, and installation of cables in PV systems.

Factors Contributing to Corrosion in PV Cables

Corrosion in PV cables can be attributed to various factors, both internal and external to the system. Understanding these factors is essential for implementing effective corrosion prevention measures. Some of the key factors contributing to corrosion in PV cables include:

1. https://www.jiangyuancables.com/metal-sheathed-inorganic-mineral-insulated-cable/ : Exposure to harsh environmental conditions such as moisture, UV radiation, temperature extremes, and airborne pollutants can accelerate the corrosion process in PV cables. Moisture, in particular, can lead to the formation of corrosion-inducing agents such as rust and oxidation.

2. Chemical Interactions: Chemical reactions between the cable materials and external agents such as salts, acids, and alkalis can cause corrosion in PV cables. These interactions can degrade the protective coatings on the cables and promote the formation of corrosion products.

3. Galvanic Corrosion: Galvanic corrosion occurs when two dissimilar metals are in contact with each other in the presence of an electrolyte. In PV cables, galvanic corrosion can occur at the connections between different metal components, leading to localized corrosion and potential failure of the system.

4. Mechanical Stress: Mechanical stress, such as bending, twisting, and vibration, can compromise the protective coatings on PV cables and expose them to the risk of corrosion. Improper installation practices and physical damage to the cables can also contribute to corrosion.

5. Manufacturing Defects: Poor quality control during the manufacturing process of PV cables can result in defects such as surface irregularities, voids, and impurities that make the cables more susceptible to corrosion. It is essential to ensure high-quality materials and manufacturing standards to prevent corrosion issues.

By addressing these factors and implementing appropriate corrosion prevention strategies, it is possible to mitigate the risks of corrosion in PV cables and enhance the reliability and longevity of PV systems.

Common Types of Corrosion in PV Cables

Corrosion in PV cables can manifest in various forms, each with distinct characteristics and mechanisms of damage. Understanding the common types of corrosion can help in identifying and effectively addressing corrosion issues in PV systems. Some of the common types of corrosion observed in PV cables include:

1. Uniform Corrosion: Uniform corrosion is the most common type of corrosion and involves the even degradation of the cable material across its surface. This type of corrosion can result from exposure to environmental elements such as moisture, oxygen, and pollutants. Uniform corrosion can weaken the structural integrity of the cables and reduce their lifespan.

2. Pitting Corrosion: Pitting corrosion is a localized form of corrosion characterized by the formation of small pits or craters on the surface of the cable material. Pitting corrosion can be particularly insidious as it can penetrate deep into the material, leading to structural weaknesses and eventual failure of the cables.

3. Crevice Corrosion: Crevice corrosion occurs in confined spaces or crevices where stagnant water or moisture can accumulate, creating an ideal environment for corrosion to occur. PV cables with cable ties, fasteners, or junction boxes are susceptible to crevice corrosion, which can lead to rapid deterioration of the cables in these areas.

4. Galvanic Corrosion: Galvanic corrosion occurs when two dissimilar metals come into contact in the presence of an electrolyte, resulting in the accelerated corrosion of the less noble metal. In PV cables, galvanic corrosion can occur at the connections between different metals, such as copper conductors and aluminum connectors, leading to localized corrosion and potential failure.

5. Stress Corrosion Cracking: Stress corrosion cracking is a type of corrosion that occurs under tensile stress in the presence of a corrosive environment. PV cables subjected to mechanical stress, such as bending or vibration, in conjunction with exposure to environmental factors, can experience stress corrosion cracking, which can compromise the integrity of the cables and result in catastrophic failure.

Strategies to Improve Corrosion Resistance in PV Cables

Enhancing the corrosion resistance of PV cables is essential for ensuring the long-term performance and reliability of PV systems. Various strategies can be employed to improve the corrosion resistance of PV cables and mitigate the risks associated with corrosion. Some effective strategies include:

1. Material Selection: Choosing high-quality materials with excellent corrosion resistance properties is crucial for designing corrosion-resistant PV cables. Materials such as tinned copper conductors, UV-resistant insulation, and corrosion-resistant coatings can help prevent corrosion and extend the lifespan of the cables.

2. Protective Coatings: Applying protective coatings to the surface of PV cables can provide an additional barrier against corrosion. Coatings such as polyethylene, polyvinyl chloride (PVC), and cross-linked polyethylene (XLPE) offer excellent resistance to moisture, chemicals, and UV radiation, enhancing the durability of the cables.

3. Corrosion Inhibitors: Incorporating corrosion inhibitors into the cable materials or coatings can help prevent corrosion by inhibiting the chemical reactions that lead to corrosion. Corrosion inhibitors such as zinc compounds, phosphates, and chromates can effectively protect the cables from corrosion in harsh environments.

4. Proper Installation: Ensuring proper installation practices, such as adequate cable support, spacing, and protection from mechanical stress, can help prevent damage to the cables and reduce the risk of corrosion. Proper grounding and bonding of metal components can also prevent galvanic corrosion in PV systems.

5. Regular Maintenance: Implementing a routine maintenance schedule for PV cables can help detect early signs of corrosion and address them before they escalate into more significant issues. Inspecting the cables for signs of corrosion, physical damage, and wear can help maintain the integrity of the system and prevent potential failures.

6. Environmental Protection: Protecting PV cables from exposure to harsh environmental conditions, such as moisture, UV radiation, and chemical pollutants, can help prolong their lifespan and maintain their corrosion resistance. Installing cable trays, conduits, and protective enclosures can shield the cables from external elements and prevent corrosion.

By implementing these strategies and adopting a proactive approach to corrosion prevention, stakeholders in the solar industry can enhance the corrosion resistance of PV cables and ensure the efficient and reliable operation of PV systems.

Conclusion

Corrosion resistance is a crucial aspect of the design and maintenance of PV cables in solar energy systems. Corrosion in PV cables can lead to various detrimental effects, including electrical resistance, mechanical weakness, and safety hazards, compromising the performance and longevity of the system. By understanding the factors contributing to corrosion, common types of corrosion, and effective strategies to improve corrosion resistance, stakeholders in the solar industry can take proactive measures to mitigate the risks of corrosion and enhance the reliability of PV systems.

Enhancing the corrosion resistance of PV cables through material selection, protective coatings, corrosion inhibitors, proper installation practices, regular maintenance, and environmental protection can help ensure the long-term performance and durability of PV systems. By prioritizing corrosion resistance in the design, selection, and installation of PV cables, stakeholders can optimize the efficiency and safety of solar energy systems and contribute to the widespread adoption of renewable energy technologies.